Before you begin:

| Step | Action |

|---|---|

| 1 |

These instructions apply to RYOBI Angle Grinders with a pin spanner locking nut. The locking nut has four holes around the centre thread to position the pin spanner:

You'll need a pin spanner to fit and remove the disc - don't attempt to remove the disc without one, as it can damage the spindle. If your Angle Grinder has a tool free locking nut (FIXTEC), see: How to fit & remove RYOBI Angle Grinder disc using a tool free locking nut. |

| 2 | Overtightening your disc can cause it to jam and potentially damage your tool – make sure when fitting your disc, you follow these steps. |

| 3 | Make sure that the disc you are trying to fit is the correct size for the grinder. See: what disc size is suitable for my RYOBI Angle Grinder? |

| 4 | Make sure the Angle Grinder and disc you've selected is suitable for your work. Not all Angle Grinders are equipped for cutting or grinding, so check that the grinder you have is up to the task by locating your product on ryobi.com.au and referring to the product description. |

| 5 | Gloves are recommended when holding or gripping the disc. |

| 6 | Before removing the disc, ensure the tool is switched off, and disconnected from power (battery or corded). |

To fit/refit the disc to an Angle Grinder:

| Step | Action |

|---|---|

| 1 | Turn the tool off, and disconnect from power (disconnect battery or unplug power chord). |

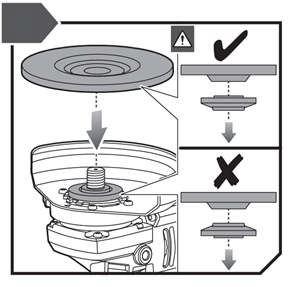

| 2 |

Place the disc so it sits flush within the inner flange.

|

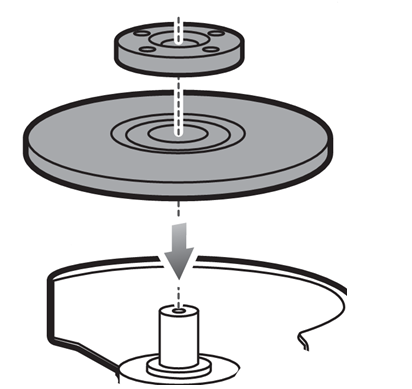

| 3 |

Place the locking nut on the Spindle / thread:

|

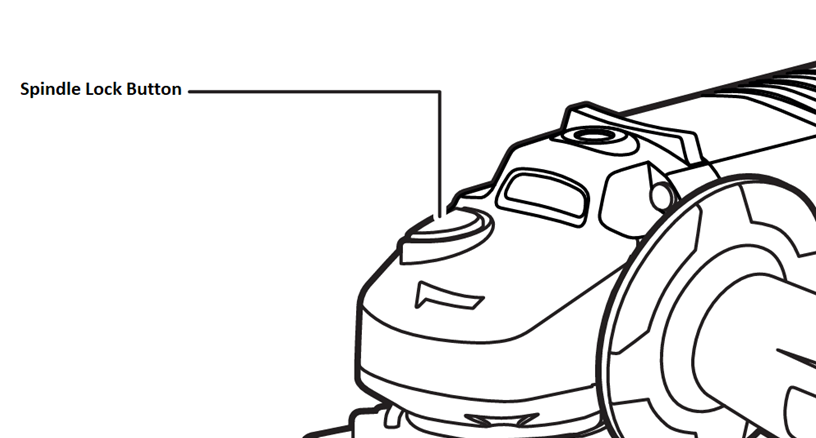

| 4 | Press and hold the spindle lock button to lock the spindle / thread from moving freely - this is located on the other side of the grinder, usually on the top. |

| 5 | Tighten the nut CLOCKWISE by hand until the nut is tight. At this point the disc should feel secure with no side-to-side movement. |

| 6 | With the spindle lock still depressed, fully tighten the disc by rotating the disc clockwise until secure - no more than a quarter turn is needed. Don't overtighten past this point - overtightening can make it difficult to remove, and cause damage to the Angle Grinder. |

| Note | If you are having difficulties tightening by hand, use a pin spanner to achieve the final tighten. |

To remove the disc from a RYOBI Angle Grinder using a pin spanner:

| Step | Action |

|---|---|

| 1 | Ensure the tool is switched off, and disconnected from power (battery or corded). |

| 2. | Then turn the grinder so the locking nut and disc are accessible. |

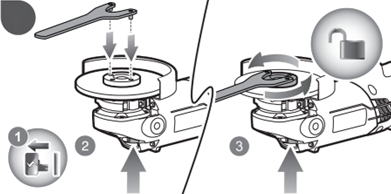

| 2 |

Place the pin spanner in two opposite holes of the locking nut and depress the spindle lock button (on the other side of the grinder, usually the top) until the disc and lock nut stop moving freely.

|

| 3 | Keeping the spindle lock button pressed in, use the pin spanner to lever, unscrew the locking nut ANTI- CLOCKWISE direction then remove the locking nut to access the disc. |

R18AG4115-0, R18AG14, RAG80125-G, EAG75100-G, EAG2023RG